Products & Services

Optimized & Industry-ready Solutions

For All Your Complicated Needs

Our latest gas station standard hydrogen refueling station design increase opportunities for small operators. The hydrogen refueling station is constructed in accordance with a competent authority that meets current global safety standards. The new station further strengthens our commitment to carbon-neutral development and supports more flexible, sustainable and affordable hydrogen technology.

We advocate and support the International Energy Agency Net Zero by 2050 (May 2021). We support the development and production of green hydrogen, and insist on a more environmentally friendly hydrogen producing. We pay attention to environmental protection and the price of hydrogen energy, so as to meet the fast and changeable choices of consumers.

Invisible gas, hydrogen, is essentially color coded depending on the type of the production used during process.

‘Green hydrogen’ is produced by electricity from intermittent renewables.

‘Grey hydrogen’ is that produced from methane with corresponding CO2 emissions.

‘Brown hydrogen’ is produced from gasified coal, with CO2 emissions.

‘Blue hydrogen’ is grey or brown hydrogen but with carbon capture and storage (typically 50-70% efficient).

‘Pink hydrogen’ or ‘yellow hydrogen’ is generated through electrolysis powered by nuclear electricity.

‘Turquoise hydrogen’ is produced from by a process called metal pyrolysis of methane, with solid carbon byproduct.

At present, at least 75 million tons (MMT) of hydrogen are produced annually in the world, and the main demand for hydrogen today is ammonia production and petroleum refining.

Our Innovations

Hydrogen Industry Focused Products!

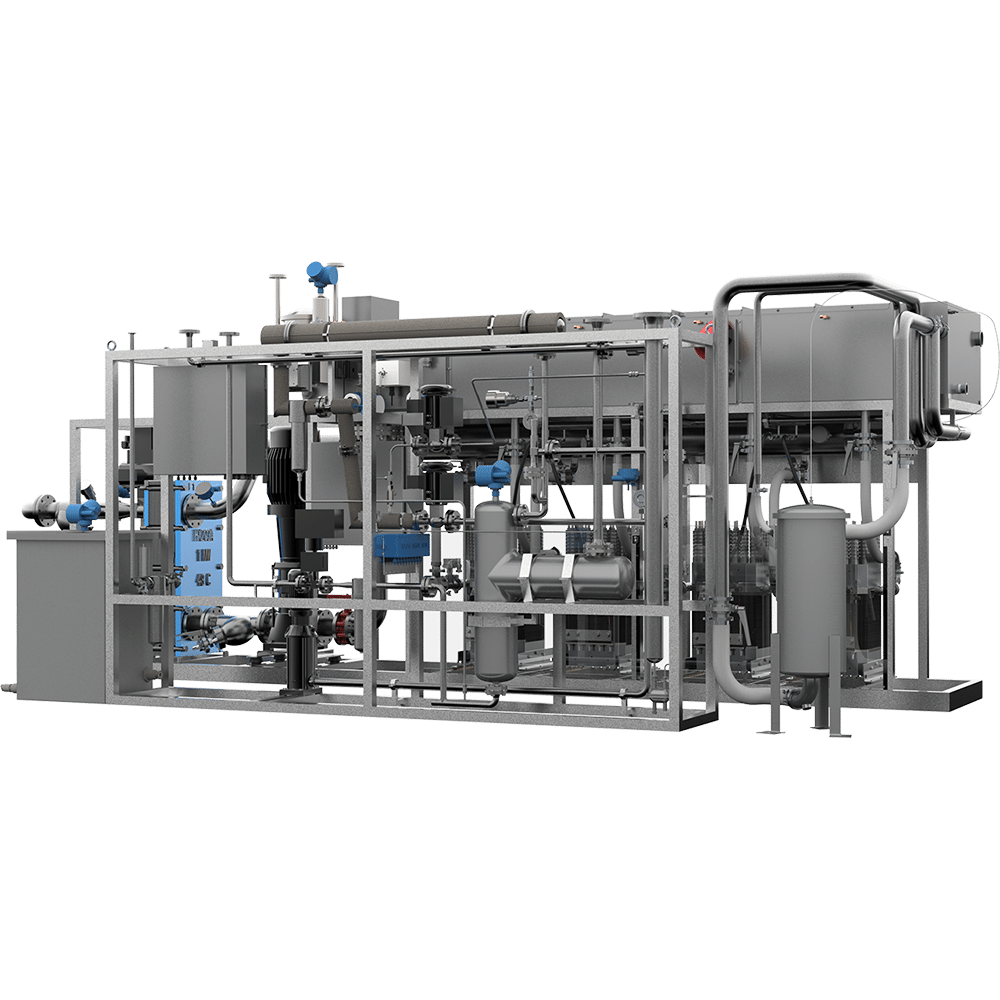

Hydrogen refueling stations

We provide complete 350 and 700 bar hydrogen refueling stations with specifications of 50, 100 and 300 Nm3/h (106, 212 and 640 kg/day or 38, 76 and 230 tons/year), equipped with reformers, compressors, High-pressure reservoirs, coolers and distributors.

The reformer is the central unit. For all the main subsystems, except for the reformer, we also pay attention to the quality and stability of all systems. While we develop ourselves, we also cooperate with other companies that have patents in each product field.

According to the latest trend, our reformer is designed with a compact structure and a built-in container size module, which can realize reasonable industrial manufacturing and safe quality control.

The figure below shows a complete hydrogen refueling station, where the reformer is the central unit.

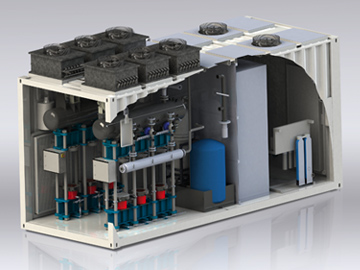

HYDROGEN PRODUCTION SYSTEMS

With cooperators, we developed a series of hydrogen generators aimed to meet demanding requirements of

small-scale hydrogen supply, using fuels such as Natural Gas, Biogas or Liquefied petroleum gas. The system offers clean,

quiet and efficient hydrogen generation under continuous operation with long service intervals.

Our standard hydrogen production system can generate 10, 20, 50, 100, 150 and 200 Nm3/h H2 respectively.

According to customer application requirements, the purity of hydrogen ranges from 99,9% to 99,999%.

Natural gas can be obtained from existing networks. Biogas can come from by the breakdown of organic matter such as food scraps and animal waste.

Components for Hydrogen Fuel Cell

Components for FCEVs (Fuel Cell Vehicles)

Integrated Hydraulic Compression

We have innovative compression solutions, which is energy efficient design and flexible hydrogen supply.